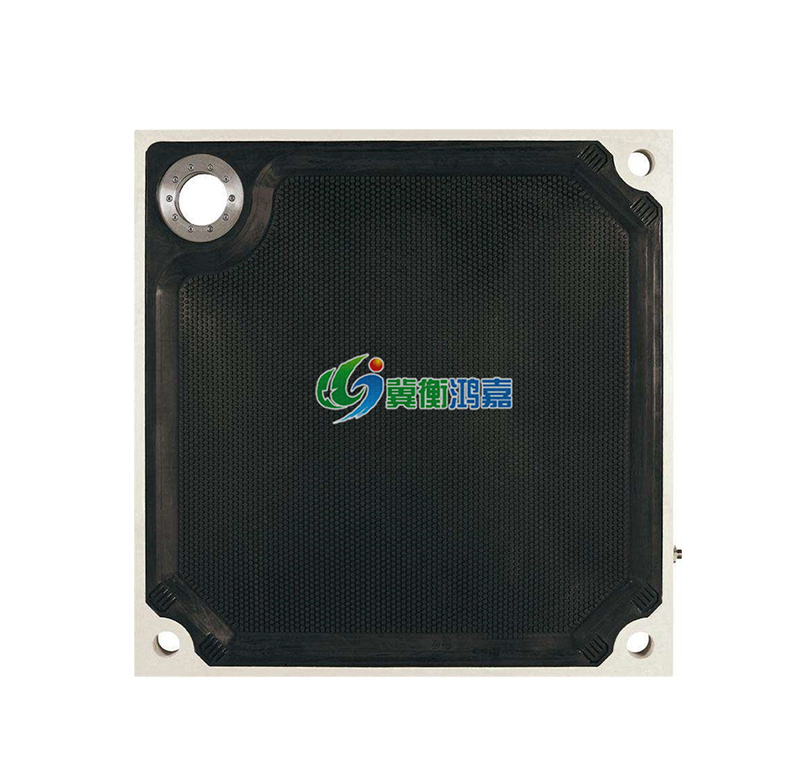

NBR nitrile rubber skeleton oil seal

The function of the skeleton oil seal is generally to isolate the parts that need to be lubricated in the transmission parts from the output parts, so as not to allow the leakage of lubricating oil. The skeleton is like the steel bars in the concrete member, which acts as a reinforcement and enables the oil seal to maintain its shape and tension. According to the skeleton type, it can be divided into inner skeleton oil seal, outer skeleton oil seal, and inner and outer skeleton oil seal. The skeleton oil seal is made of high-quality nitrile rubber and steel plate, with stable quality and long service life. Widely used in automobiles, motorcycle crankshafts, camshafts, differentials, shock absorbers, engines, axles, front and rear wheels and other parts.

Keyword:

Categroy:

NBR nitrile rubber skeleton oil seal

Hotline:

NBR nitrile rubber skeleton oil seal

The function of the skeleton oil seal is generally to isolate the parts that need to be lubricated in the transmission parts from the output parts, so that the lubricating oil will not leak. The skeleton is like the steel bars in the concrete member, which acts as a reinforcement and enables the oil seal to maintain its shape and tension. According to the skeleton type, it can be divided into inner skeleton oil seal, outer skeleton oil seal, and inner and outer skeleton oil seal. The skeleton oil seal is made of high-quality nitrile rubber and steel plate, with stable quality and long service life. Widely used in automobiles, motorcycle crankshafts, camshafts, differentials, shock absorbers, engines, axles, front and rear wheels and other parts.

1. Prevent sediment, dust, moisture, etc. from intruding into the bearing from outside;

2. Limit the leakage of lubricating oil in the bearing. The requirements for the oil seal are that the dimensions (inner diameter, outer diameter and thickness) should meet the regulations; appropriate elasticity is required,

It can properly clamp the shaft and play a sealing role; it must be heat-resistant, wear-resistant, strong, resistant to media (oil or water, etc.), and has a long service life.

The following points should be paid attention to when using the oil seal reasonably:

(1) Shaft speed Due to design and structural reasons, high-speed shafts should use high-speed oil seals, low-speed shafts should use low-speed oil seals, and low-speed oil seals cannot be used on high-speed shafts, and vice versa.

(2) When the ambient temperature is high, polyacrylate or silicon, fluorine, and silicon fluorine rubber should be selected. And should try to lower the oil temperature in the tank. When the operating temperature is too low, cold-resistant rubber should be used.

(3) The oil seal with general pressure has poor pressure bearing capacity, and the oil seal will deform when the pressure is too large. Under the condition of excessive pressure, a pressure-resistant bearing ring or a reinforced pressure-resistant oil seal should be used.

(4) The degree of eccentricity on the installation When the eccentricity of the oil seal and the shaft is too large, the sealing performance will be deteriorated, especially when the shaft speed is high. If the eccentricity is too large, an oil seal with a "W"-shaped section can be used.

(5) The surface finish of the shaft directly affects the service life of the oil seal, that is, the higher the shaft finish, the longer the service life of the oil seal.

(6) Note that there should be a certain amount of lubricating oil on the lip of the oil seal.

(7) Pay special attention to prevent dust from immersing in the oil seal.

Prev

None

Next

Releate Product

Inquiry