Metal Wound Gasket

Metal spiral wound gaskets are made of high-quality SUS304, SUS316 ("V" shape or "W" shape) metal strips and other alloy materials and graphite, asbestos, PTFE, non-asbestos and other soft materials alternately overlapped and spirally wound. The metal strips are fixed by spot welding at the beginning and end. Metal spiral wound gasket is the gasket with the best resilience among semi-metal gaskets

Keyword:

Categroy:

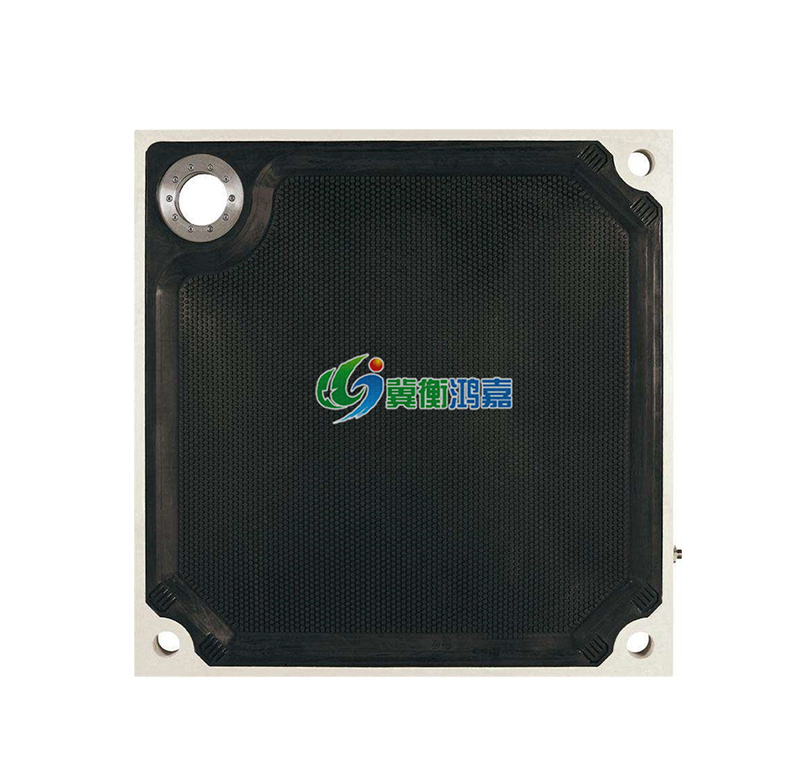

Flange Gasket

Hotline:

Metal Wound Gasket

Metal spiral wound gaskets are made of high-quality SUS304, SUS316 (“V” shape or “W” shape) metal strips and other alloy materials and graphite, asbestos, PTFE, non-asbestos and other soft materials alternately overlap each other It is spirally wound, and the metal strip is fixed by spot welding at the beginning and end. Metal spiral wound gasket is the gasket with the best resilience among semi-metal gaskets. The structural density of metal spiral wound gasket can be made according to different locking force requirements, and the inner and outer steel rings are used to control its maximum compression, winding The surface accuracy of the flange sealing surface in contact with the gasket is not high. Metal spiral wound gaskets are especially suitable for occasions where the load is uneven, the joint force is easy to relax, the temperature and pressure change periodically, and there is impact or vibration. Spiral wound gasket is a static sealing original for flange connection processing such as valves, pumps, heat exchangers, towers, manholes, hand holes, etc.

(1). Metal strip material

A. Use 08F, 0Cr13, 0Cr18Ni19Ti, 0Cr18Ni9Ti, 00Cr18Ni10, 0Cr18Ni12Mo2Ti, 00Cr17Ni14Mo2 and other cold-rolled steel strips with a thickness of 0.15mm~0.25mm, or negotiate between the supplier and the buyer. B. The metal strip is a pre-formed V-shaped or W-shaped narrow strip, the surface should be smooth, clean, and should not have roughness, cracks, scratches, pits and rust spots and other defects C. Stainless steel Hardness value HV≤200 D. The width of the general steel strip is 3.2mm, 4.5mm.8mm

(2). Non-metallic tape materials A Non-metallic filled tapes are specially made asbestos tapes, flexible graphite tapes, PTFE tapes, non-asbestos fiber tapes, ceramic fibers and mica tapes. The thickness of the belt is 0.3-1.0mm. B. The loss on ignition of the special asbestos must be ≤25% C. The chloride ion content of the non-metallic belt≤100PPM D. The recommended use of various media and various non-metallic belts Temperature and pressure E. The width of the general steel strip is 3.2mm, 4.5mm.8mm

(3), performance and characteristics

1. Wide range of applicable working conditions. Can withstand high temperature, high pressure and adapt to ultra-low temperature or vacuum conditions. By changing the material combination of the gasket, the chemical corrosion of the gasket by various media can be solved.

2. Strong stress compensation ability. In the working position with frequent temperature and pressure fluctuations, the sealing performance is stable and reliable.

3. Excellent sealing performance.

4. The surface accuracy requirements for the flange sealing in contact with the gasket are not high.

5. Easy installation and low gasket preload pressure.

(4) Types of gaskets

1. A. Spiral wound gaskets are divided into four forms: basic type, with inner ring type, with outer ring type, with inner and outer ring type. B. Spiral wound gaskets for heat exchangers are generally divided into: basic type and inner and outer ring type.

2. Materials commonly used: A. Steel strip: 08F, 0Cr18Ni9(304), 0Cr18Ni9Ti, 1Cr18Ni9Ti(321), 0Cr17Ni12, M02(316), 00Cr17Ni14M02(316L) B. Steel plate for inner and outer rings (cold rolled): outer ring : Low carbon steel, 0Cr13, oCr18Ni9 Inner ring: usually the same material as the steel strip or negotiated. C. Non-metallic belt: flexible graphite, special asbestos, polytetrafluoroethylene, non-asbestos paper. 4. Use range 1. Use temperature: -196℃-700℃ (not higher than 600℃ in oxidizing medium) 2. Use pressure: ≤25MPa 3. Gasket coefficient: m=2.5-4 4. Minimum preload Specific pressure: y=68MPa

Prev

Next

Prev

anise pad

Next

Releate Product

Inquiry