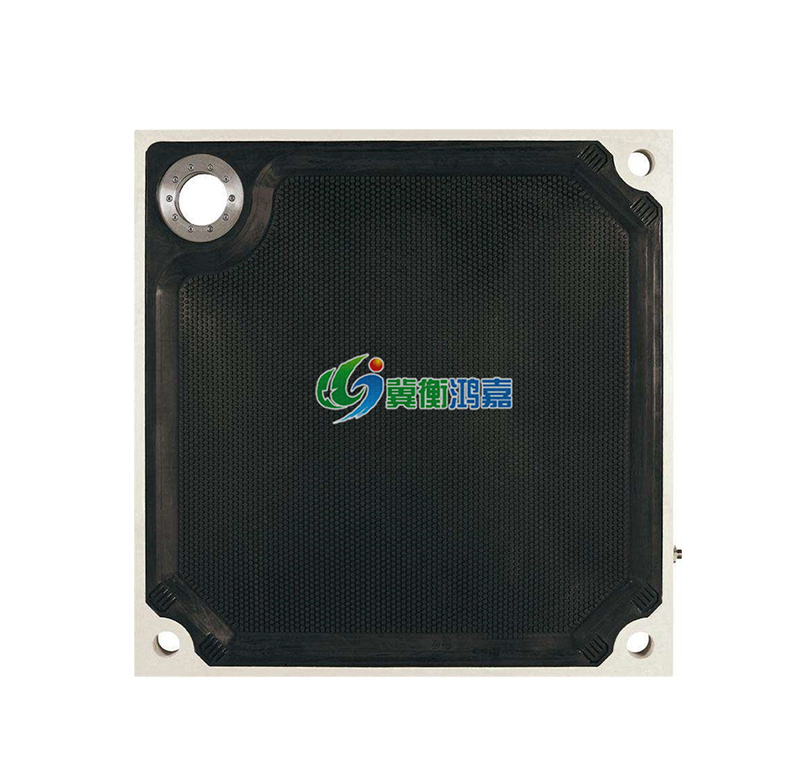

Plate Heat Exchanger Gasket

The plate heat exchanger is a new type of high-efficiency heat exchanger made of a series of metal sheets with a certain corrugated shape. Thin rectangular channels are formed between various plates, and heat is exchanged through the plates. Plate heat exchanger is an ideal equipment for heat exchange of liquid-liquid, liquid-vapor. It has the characteristics of high heat exchange efficiency, small heat loss, compact and lightweight structure, small footprint, convenient installation and cleaning, wide application and long service life. Under the same pressure loss, the heat transfer coefficient is 3-5 times higher than that of the tubular heat exchanger, the floor area is one third of that of the tubular heat exchanger, and the heat recovery rate can be as high as 90% or more. There are three main types of plates: herringbone corrugated plate, horizontal straight corrugated plate and tumor-shaped plate.

Keyword:

Categroy:

Plate Heat Exchanger Gasket

Hotline:

Plate Heat Exchanger Gasket

The plate heat exchanger is a new type of high-efficiency heat exchanger made of a series of metal sheets with a certain corrugated shape. Thin rectangular channels are formed between various plates, and heat is exchanged through the plates. Plate heat exchanger is an ideal equipment for heat exchange of liquid-liquid, liquid-vapor. It has the characteristics of high heat exchange efficiency, small heat loss, compact and lightweight structure, small footprint, convenient installation and cleaning, wide application and long service life. Under the same pressure loss, the heat transfer coefficient is 3-5 times higher than that of the tubular heat exchanger, the floor area is one third of that of the tubular heat exchanger, and the heat recovery rate can be as high as 90% or more. There are three main types of plates: herringbone corrugated plate, horizontal straight corrugated plate and tumor-shaped plate.

Product Features:

1. High efficiency and energy saving: its heat transfer coefficient is 3000~4500kcal/m2·°C·h, which is 3~5 times higher than the thermal efficiency of shell and tube heat exchangers.

2. Compact structure: The plates of the plate heat exchanger are closely arranged. Compared with other types of heat exchangers, the plate heat exchanger occupies less floor space and space, and the plate heat exchanger with the same area for heat exchange is only the tube 1/5 of the shell heat exchanger.

3. Easy to clean and easy to assemble and disassemble: the plate heat exchanger is clamped by clamping bolts, so it is easy to disassemble and assemble, and it can be opened and cleaned at any time.

4. Long service life: The plate heat exchanger is pressed by stainless steel or titanium alloy plates, which can resist various corrosive media.

5. Strong adaptability: The plate heat exchanger plate is an independent component, and the process can be increased or decreased at will according to the requirements, in various forms; it can be applied to various different process requirements.

6. No liquid leakage, the sealing groove of the plate heat exchanger is provided with a liquid leakage channel, and various media will not be connected.

Application:

Plate heat exchangers have been widely used in metallurgy, mining, petroleum, chemical industry, electric power, medicine, food, chemical fiber, papermaking, light textile, shipbuilding, heating and other departments, and can be used for heating, cooling, evaporation, condensation, sterilization, waste heat recycling, etc.

Prev

None

Next

Releate Product

Inquiry